說明文件

comments powered by Disqus

comments powered by Disqus

PWM 的 應用範例

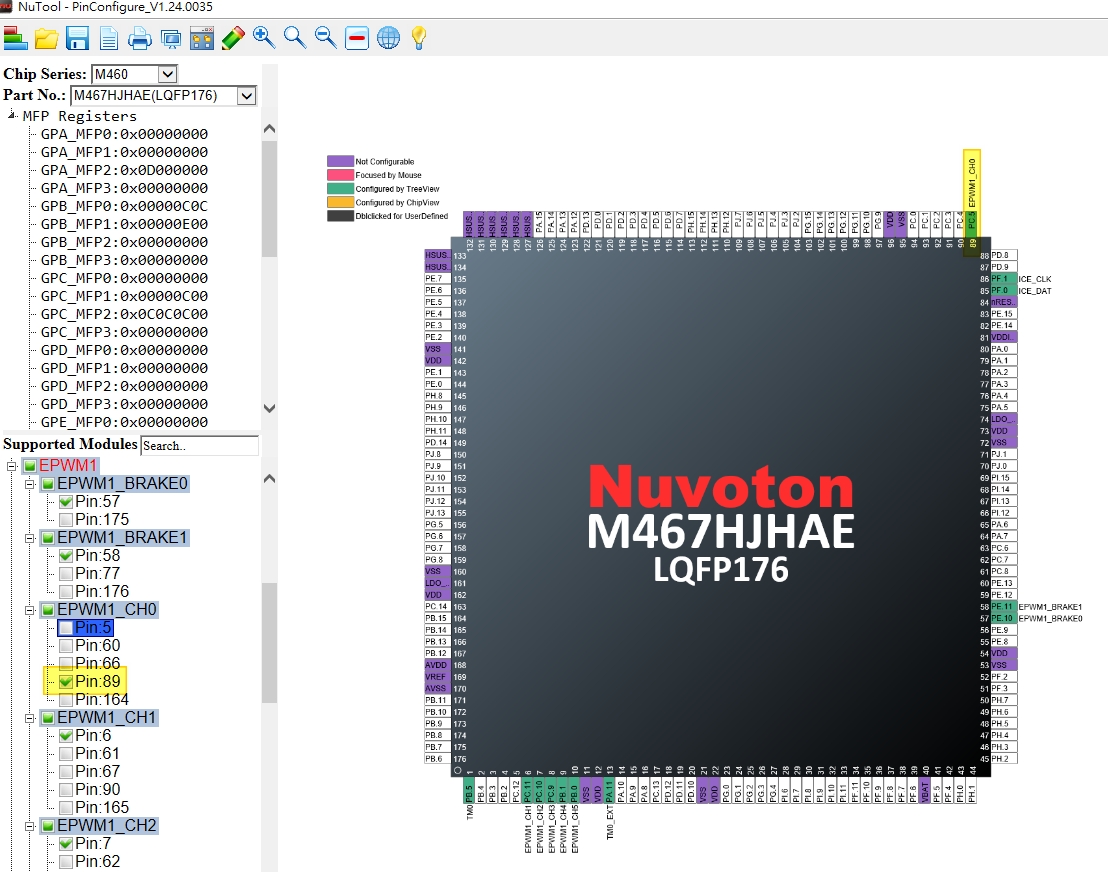

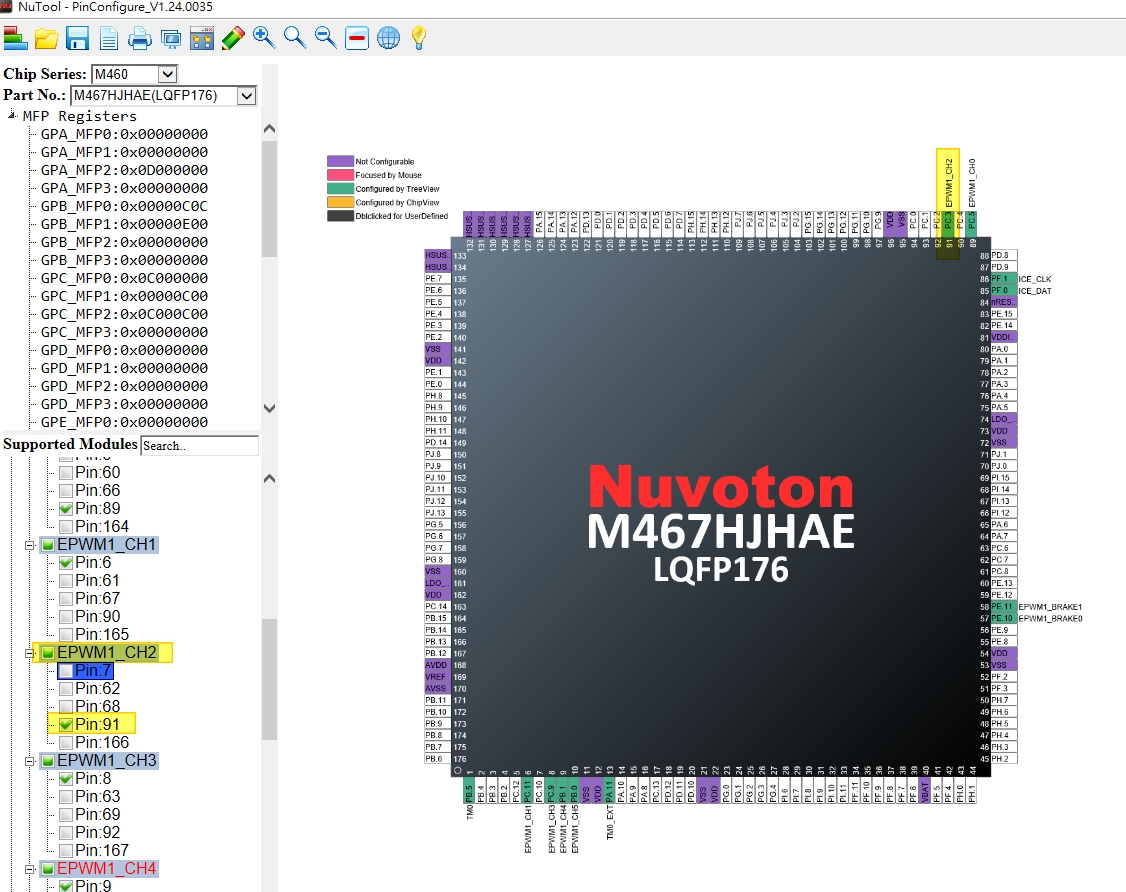

BSP EPWM

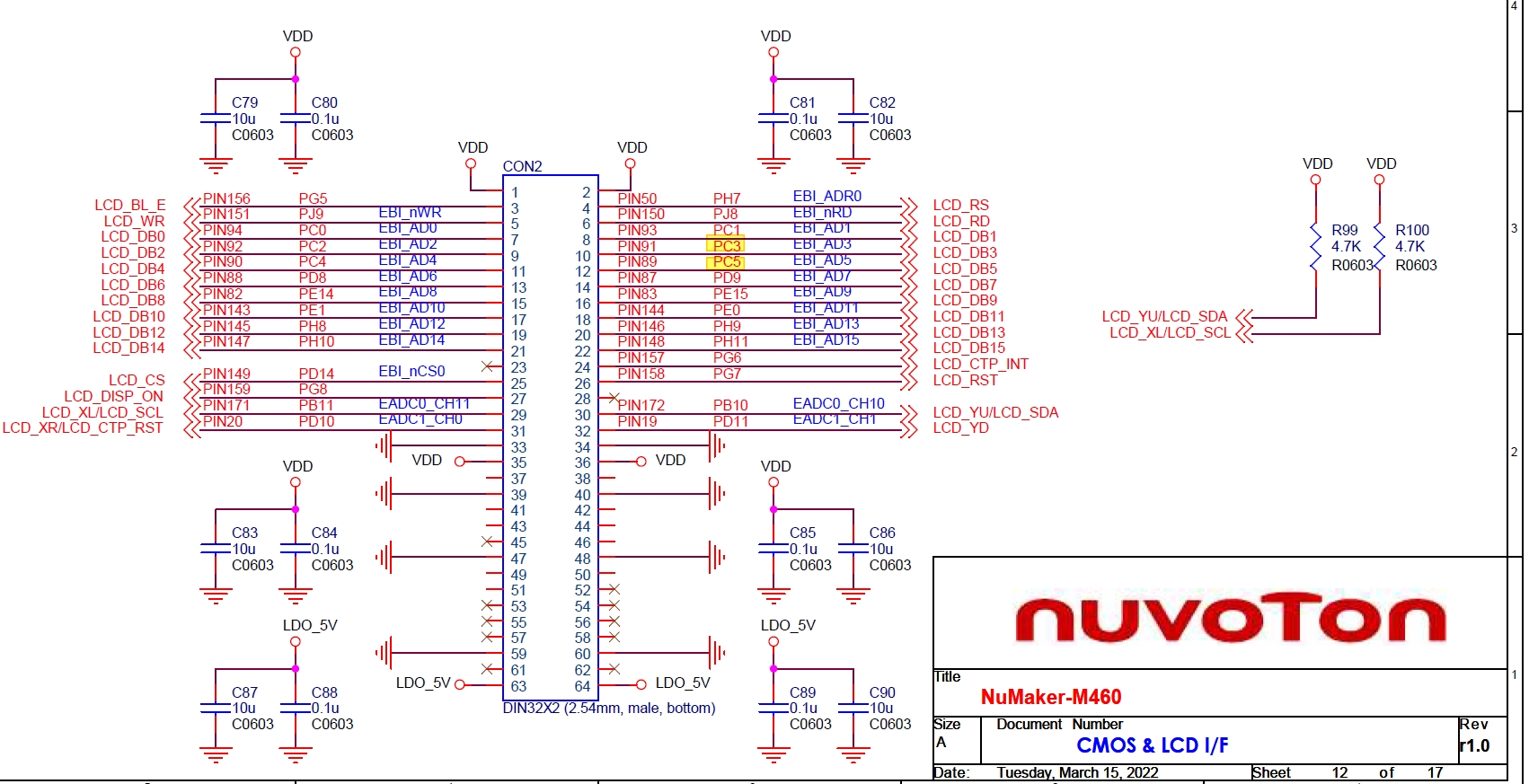

我是找 BSP 使用的 PWM PIN 角, 但還是用pinconfigure 看一下

所以根據上圖以及BSP ,

PWM1 的 Channel0

會發訊號 給

PWM1 的 Channel2

查看開發版的電路圖 是哪兩根PIN

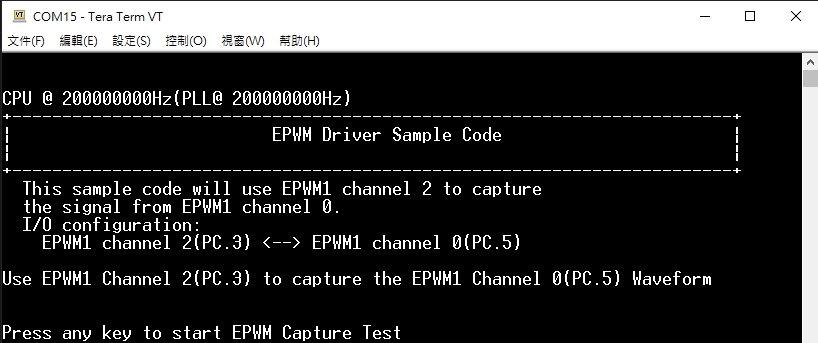

EPWM_Capture BSP 的 console

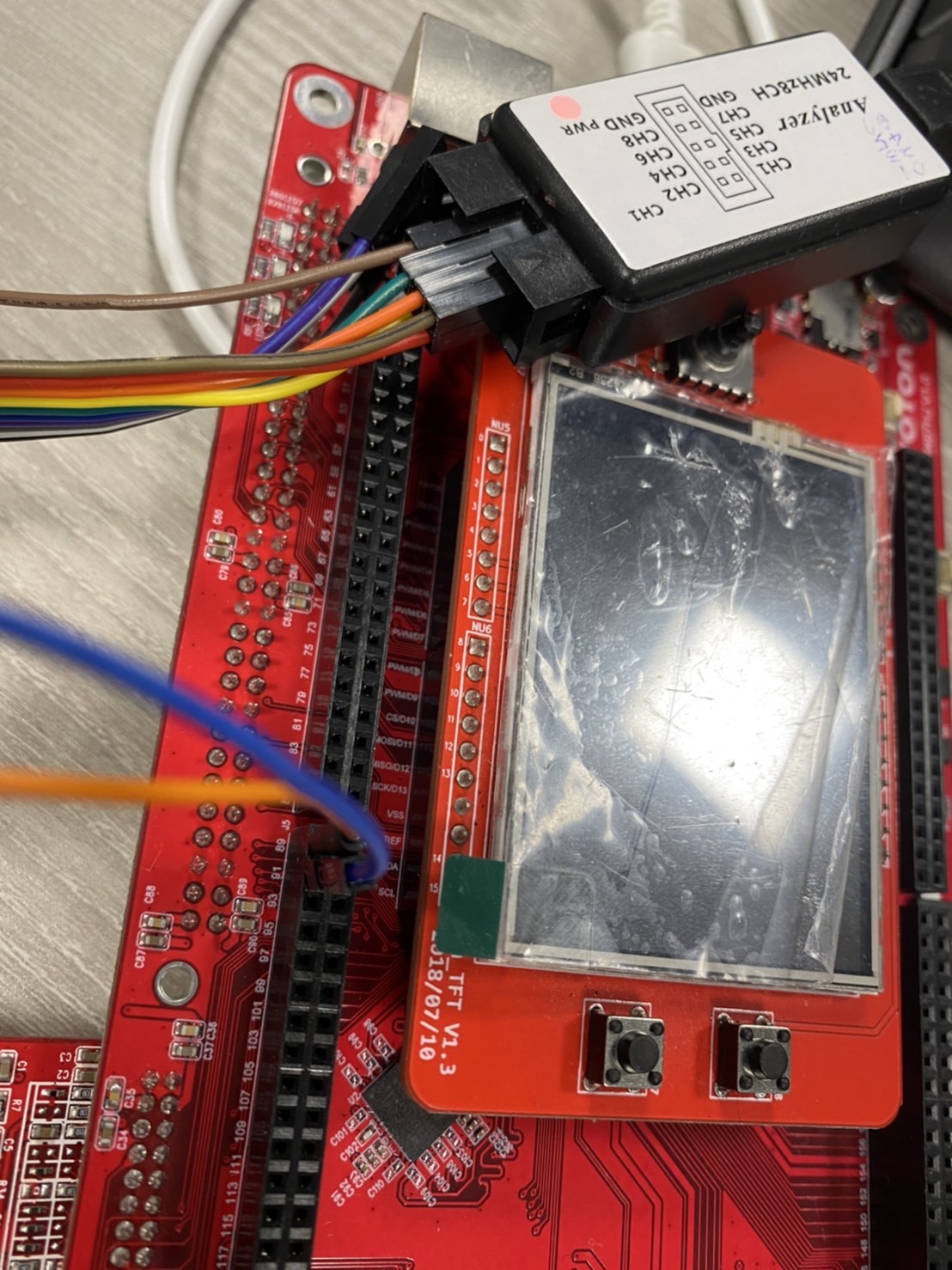

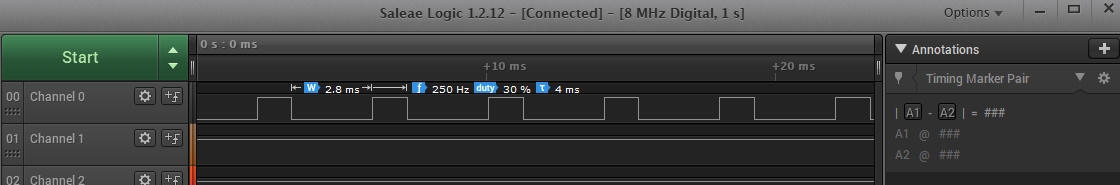

量測邏輯分析儀

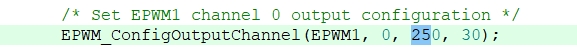

EPWM1 的 channel0 發 250 Hz pwm 訊號 30% duty

/**************************************************************************//**

* @file main.c

* @version V3.00

* @brief Capture the EPWM1 Channel 0 waveform by EPWM1 Channel 2.

*

* @copyright SPDX-License-Identifier: Apache-2.0

* @copyright Copyright (C) 2021 Nuvoton Technology Corp. All rights reserved.

******************************************************************************/

#include <stdio.h>

#include "NuMicro.h"

/*---------------------------------------------------------------------------------------------------------*/

/* Macro, type and constant definitions */

/*---------------------------------------------------------------------------------------------------------*/

/*---------------------------------------------------------------------------------------------------------*/

/* Global variables */

/*---------------------------------------------------------------------------------------------------------*/

void CalPeriodTime(EPWM_T *EPWM, uint32_t u32Ch);

void SYS_Init(void);

void UART0_Init(void);

/*--------------------------------------------------------------------------------------*/

/* Capture function to calculate the input waveform information */

/* au32Count[4] : Keep the internal counter value when input signal rising / falling */

/* happens */

/* */

/* time A B C D */

/* ___ ___ ___ ___ ___ ___ ___ ___ */

/* ____| |_| |_| |_| |_| |_| |_| |_| |_____ */

/* index 0 1 2 3 */

/* */

/* The capture internal counter down count from 0x10000, and reload to 0x10000 after */

/* input signal falling happens (Time B/C/D) */

/*--------------------------------------------------------------------------------------*/

void CalPeriodTime(EPWM_T *EPWM, uint32_t u32Ch)

{

uint16_t au16Count[4];

uint32_t u32i;

uint16_t u16RisingTime, u16FallingTime, u16HighPeriod, u16LowPeriod, u16TotalPeriod;

/* Clear Capture Falling Indicator (Time A) */

EPWM_ClearCaptureIntFlag(EPWM, u32Ch, EPWM_CAPTURE_INT_FALLING_LATCH);

/* Wait for Capture Falling Indicator */

while((EPWM1->CAPIF & EPWM_CAPIF_CFLIF2_Msk) == 0);

/* Clear Capture Falling Indicator (Time B)*/

EPWM_ClearCaptureIntFlag(EPWM, u32Ch, EPWM_CAPTURE_INT_FALLING_LATCH);

u32i = 0;

while(u32i < 4)

{

/* Wait for Capture Falling Indicator */

while(EPWM_GetCaptureIntFlag(EPWM, u32Ch) < 2);

/* Clear Capture Falling and Rising Indicator */

EPWM_ClearCaptureIntFlag(EPWM, u32Ch, EPWM_CAPTURE_INT_FALLING_LATCH | EPWM_CAPTURE_INT_RISING_LATCH);

/* Get Capture Falling Latch Counter Data */

au16Count[u32i++] = (uint16_t)EPWM_GET_CAPTURE_FALLING_DATA(EPWM, u32Ch);

/* Wait for Capture Rising Indicator */

while(EPWM_GetCaptureIntFlag(EPWM, u32Ch) < 2);

/* Clear Capture Rising Indicator */

EPWM_ClearCaptureIntFlag(EPWM, u32Ch, EPWM_CAPTURE_INT_RISING_LATCH);

/* Get Capture Rising Latch Counter Data */

au16Count[u32i++] = (uint16_t)EPWM_GET_CAPTURE_RISING_DATA(EPWM, u32Ch);

}

u16RisingTime = au16Count[1];

u16FallingTime = au16Count[0];

u16HighPeriod = au16Count[1] - au16Count[2];

u16LowPeriod = (uint16_t)(0x10000 - au16Count[1]);

u16TotalPeriod = (uint16_t)(0x10000 - au16Count[2]);

printf("\nEPWM generate: \nHigh Period=17141 ~ 17143, Low Period=39999 ~ 40001, Total Period=57141 ~ 57143\n");

printf("\nCapture Result: Rising Time = %d, Falling Time = %d \nHigh Period = %d, Low Period = %d, Total Period = %d.\n\n",

u16RisingTime, u16FallingTime, u16HighPeriod, u16LowPeriod, u16TotalPeriod);

if((u16HighPeriod < 17141) || (u16HighPeriod > 17143) || (u16LowPeriod < 39999) || (u16LowPeriod > 40001) || (u16TotalPeriod < 57141) || (u16TotalPeriod > 57143))

printf("Capture Test Fail!!\n");

else

printf("Capture Test Pass!!\n");

}

void SYS_Init(void)

{

/* Set PF multi-function pins for XT1_OUT(PF.2) and XT1_IN(PF.3) */

SET_XT1_OUT_PF2();

SET_XT1_IN_PF3();

/*---------------------------------------------------------------------------------------------------------*/

/* Init System Clock */

/*---------------------------------------------------------------------------------------------------------*/

/* Enable HIRC and HXT clock */

CLK_EnableXtalRC(CLK_PWRCTL_HIRCEN_Msk | CLK_PWRCTL_HXTEN_Msk);

/* Wait for HIRC and HXT clock ready */

CLK_WaitClockReady(CLK_STATUS_HIRCSTB_Msk | CLK_STATUS_HXTSTB_Msk);

/* Set PCLK0 and PCLK1 to HCLK/2 */

CLK->PCLKDIV = (CLK_PCLKDIV_APB0DIV_DIV2 | CLK_PCLKDIV_APB1DIV_DIV2);

/* Set core clock to 200MHz */

CLK_SetCoreClock(200000000);

/* Enable all GPIO clock */

CLK->AHBCLK0 |= CLK_AHBCLK0_GPACKEN_Msk | CLK_AHBCLK0_GPBCKEN_Msk | CLK_AHBCLK0_GPCCKEN_Msk | CLK_AHBCLK0_GPDCKEN_Msk |

CLK_AHBCLK0_GPECKEN_Msk | CLK_AHBCLK0_GPFCKEN_Msk | CLK_AHBCLK0_GPGCKEN_Msk | CLK_AHBCLK0_GPHCKEN_Msk;

CLK->AHBCLK1 |= CLK_AHBCLK1_GPICKEN_Msk | CLK_AHBCLK1_GPJCKEN_Msk;

/* Enable UART0 module clock */

CLK_EnableModuleClock(UART0_MODULE);

/* Select UART0 module clock source as HIRC and UART0 module clock divider as 1 */

CLK_SetModuleClock(UART0_MODULE, CLK_CLKSEL1_UART0SEL_HIRC, CLK_CLKDIV0_UART0(1));

/* Enable EPWM1 module clock */

CLK_EnableModuleClock(EPWM1_MODULE);

/* Select EPWM1 module clock source */

CLK_SetModuleClock(EPWM1_MODULE, CLK_CLKSEL2_EPWM1SEL_PCLK1, 0);

/*---------------------------------------------------------------------------------------------------------*/

/* Init I/O Multi-function */

/*---------------------------------------------------------------------------------------------------------*/

/* Set multi-function pins for UART0 RXD and TXD */

SET_UART0_RXD_PB12();

SET_UART0_TXD_PB13();

/* Set multi-function pin for EPWM */

SET_EPWM1_CH0_PC5();

SET_EPWM1_CH2_PC3();

}

void UART0_Init(void)

{

/*---------------------------------------------------------------------------------------------------------*/

/* Init UART */

/*---------------------------------------------------------------------------------------------------------*/

/* Configure UART0 and set UART0 baud rate */

UART_Open(UART0, 115200);

}

/*---------------------------------------------------------------------------------------------------------*/

/* Main Function */

/*---------------------------------------------------------------------------------------------------------*/

int32_t main(void)

{

/* Init System, IP clock and multi-function I/O

In the end of SYS_Init() will issue SYS_LockReg()

to lock protected register. If user want to write

protected register, please issue SYS_UnlockReg()

to unlock protected register if necessary */

/* Unlock protected registers */

SYS_UnlockReg();

/* Init System, IP clock and multi-function I/O */

SYS_Init();

/* Lock protected registers */

SYS_LockReg();

/* Init UART to 115200-8n1 for print message */

UART0_Init();

printf("\n\nCPU @ %dHz(PLL@ %dHz)\n", SystemCoreClock, PllClock);

printf("+------------------------------------------------------------------------+\n");

printf("| EPWM Driver Sample Code |\n");

printf("| |\n");

printf("+------------------------------------------------------------------------+\n");

printf(" This sample code will use EPWM1 channel 2 to capture\n the signal from EPWM1 channel 0.\n");

printf(" I/O configuration:\n");

printf(" EPWM1 channel 2(PC.3) <--> EPWM1 channel 0(PC.5)\n\n");

printf("Use EPWM1 Channel 2(PC.3) to capture the EPWM1 Channel 0(PC.5) Waveform\n");

while(1)

{

printf("\n\nPress any key to start EPWM Capture Test\n");

getchar();

/*--------------------------------------------------------------------------------------*/

/* Set the EPWM1 Channel 0 as EPWM output function. */

/*--------------------------------------------------------------------------------------*/

/* Assume EPWM output frequency is 250Hz and duty ratio is 30%, user can calculate EPWM settings by follows.(up counter type)

duty ratio = (CMR)/(CNR+1)

cycle time = CNR+1

High level = CMR

EPWM clock source frequency = PLL/2 = 100000000

(CNR+1) = EPWM clock source frequency/prescaler/EPWM output frequency

= 100000000/7/250 = 57142

(Note: CNR is 16 bits, so if calculated value is larger than 65536, user should increase prescale value.)

CNR = 57141

duty ratio = 30% ==> (CMR)/(CNR+1) = 30%

CMR = 17142

Prescale value is 6 : prescaler= 7

*/

/* Set EPWM1 channel 0 output configuration */

EPWM_ConfigOutputChannel(EPWM1, 0, 250, 30);

/* Enable EPWM Output path for EPWM1 channel 0 */

EPWM_EnableOutput(EPWM1, EPWM_CH_0_MASK);

/* Enable Timer for EPWM1 channel 0 */

EPWM_Start(EPWM1, EPWM_CH_0_MASK);

/*--------------------------------------------------------------------------------------*/

/* Set the EPWM1 channel 2 for capture function */

/*--------------------------------------------------------------------------------------*/

/* If input minimum frequency is 250Hz, user can calculate capture settings by follows.

Capture clock source frequency = PLL = 100000000 in the sample code.

(CNR+1) = Capture clock source frequency/prescaler/minimum input frequency

= 100000000/7/250 = 57142

(Note: CNR is 16 bits, so if calculated value is larger than 65536, user should increase prescale value.)

CNR = 0xFFFF

(Note: In capture mode, user should set CNR to 0xFFFF to increase capture frequency range.)

Capture unit time = 1/Capture clock source frequency/prescaler

70 ns = 1/100000000/7

*/

/* Set EPWM1 channel 2 capture configuration */

EPWM_ConfigCaptureChannel(EPWM1, 2, 70, 0);

/* Enable Timer for EPWM1 channel 2 */

EPWM_Start(EPWM1, EPWM_CH_2_MASK);

/* Enable Capture Function for EPWM1 channel 2 */

EPWM_EnableCapture(EPWM1, EPWM_CH_2_MASK);

/* Enable falling capture reload */

EPWM1->CAPCTL |= EPWM_CAPCTL_FCRLDEN2_Msk;

/* Wait until EPWM1 channel 2 Timer start to count */

while((EPWM1->CNT[2]) == 0);

/* Capture the Input Waveform Data */

CalPeriodTime(EPWM1, 2);

/*------------------------------------------------------------------------------------------------------------*/

/* Stop EPWM1 channel 0 (Recommended procedure method 1) */

/* Set EPWM Timer loaded value(Period) as 0. When EPWM internal counter(CNT) reaches to 0, disable EPWM Timer */

/*------------------------------------------------------------------------------------------------------------*/

/* Set EPWM1 channel 0 loaded value as 0 */

EPWM_Stop(EPWM1, EPWM_CH_0_MASK);

/* Wait until EPWM1 channel 0 Timer Stop */

while((EPWM1->CNT[0] & EPWM_CNT0_CNT_Msk) != 0);

/* Disable Timer for EPWM1 channel 0 */

EPWM_ForceStop(EPWM1, EPWM_CH_0_MASK);

/* Disable EPWM Output path for EPWM1 channel 0 */

EPWM_DisableOutput(EPWM1, EPWM_CH_0_MASK);

/*------------------------------------------------------------------------------------------------------------*/

/* Stop EPWM1 channel 2 (Recommended procedure method 1) */

/* Set EPWM Timer loaded value(Period) as 0. When EPWM internal counter(CNT) reaches to 0, disable EPWM Timer */

/*------------------------------------------------------------------------------------------------------------*/

/* Set loaded value as 0 for EPWM1 channel 2 */

EPWM_Stop(EPWM1, EPWM_CH_2_MASK);

/* Wait until EPWM1 channel 2 current counter reach to 0 */

while((EPWM1->CNT[2] & EPWM_CNT2_CNT_Msk) != 0);

/* Disable Timer for EPWM1 channel 2 */

EPWM_ForceStop(EPWM1, EPWM_CH_2_MASK);

/* Disable Capture Function and Capture Input path for EPWM1 channel 2*/

EPWM_DisableCapture(EPWM1, EPWM_CH_2_MASK);

/* Clear Capture Interrupt flag for EPWM1 channel 2 */

EPWM_ClearCaptureIntFlag(EPWM1, 2, EPWM_CAPTURE_INT_FALLING_LATCH);

}

}

/*** (C) COPYRIGHT 2021 Nuvoton Technology Corp. ***/